Screw Jacks Used in Log Construction

Features

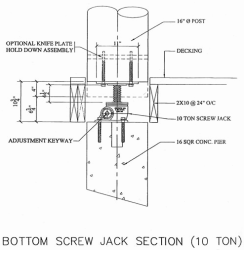

- 5 and 10 ton jacks Type 2: load pad Upright 6” vertical travel

- 5-ton jack at top of column, 10-ton jack at bottom of column

- Special hexagon input shafts

- Weatherized

The use of jacks in log construction is an innovative solution that was used by a log home building contractor and proposed by Trans-Quip, Canadian Master Distributor of Joyce jacks and power train components.

Log homes present a unique challenge because their support columns are exterior to the structure unlike residential homes which have support columns in the basement. Consequently, in log construction the screw and nut set-up is completely exposed and in many instances difficult to access. Additionally, the builder can only level in a downward direction.

Trans-Quip’s application of jacks solved these problems. Instead of using a large wrench, a small powered tool is used

to drive the input shaft to the jack. This allows the placing of the jack access in the best possible location and requires only room enough to engage the tool. The time required to remove and replace coverings in order to adjust the screw is reduced.

A further advantage is the ability to adjust upward as well as downward. This means that levelling time is dramatically reduced, a major benefit to log construction professionals.

Trans-Quip is proud to have pioneered this innovative use of jacks in log construction.