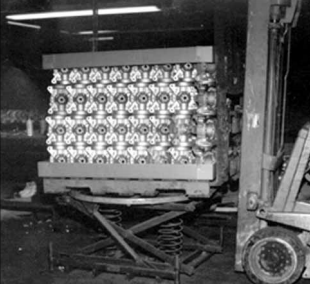

PalletPal Fully Automatic Spring Actuated Level Loader Used in an Aluminum Die-Castings Plant

| Model | Capacity | Lowered Height | Raised Height |

| PalletPal® Fully Automatic Spring Actuated |

4,500 lbs. | 9.5” | 28” |

Features

- Heavy-duty springs bring pallet to most convenient height

- Low-friction bearing-supported turntable for near-side loading and unloading

- Fork pockets for relocation by fork truck

- Equipment is maintenance free

PalletPal Speeds Pallet Loading and Reduces Risk of Injury for Die Cast Manufacturer

A Texas based manufacturer of custom aluminum die-castings maintains over 300 workers in a 135,000 square foot plant. Management was concerned with a pallet-loading operation that involved constant stooping and bending as workers loaded finished castings for shipment.

The Plant Manager selected the PalletPal® Level Loader from Southworth Products after an in-plant demonstration. “The equipment seemed expressly

designed for our needs” the manager said. Formerly, the finished castings were placed on a pallet resting on the floor. Each pallet holds about 200 pieces in five layers, and workers had to inspect, package and load as many as 700 or more five to ten pound castings per shift. It was tiring work and fatigue was a real problem.” Since implementing the PalletPal, it has virtually eliminated tiresome bending and stooping of

the operators. The company purchased an additional 3 units for similar loading-unloading applications in the plant.

PalletPal Features

In operation, the PalletPal lowers or elevates as weight is added or removed. No power is needed. The unit uses the stored energy of load-calibrated, heavy duty springs to keep pallets at the most convenient loading or unloading height. And a low friction, bearing supported turntable revolves to make all parts of the load easily accessible without reaching and stretching.