Screw Jacks Used in Positioning Tables

| Model | Capacity | Ratio | Rise |

| Screw Type WJ3230-12-UP-T4 w/b |

30 ton | 32:1 | 12” |

Features

- Boot covers protect against dust contamination

- Clevis end and pin

- Screws are self-locking

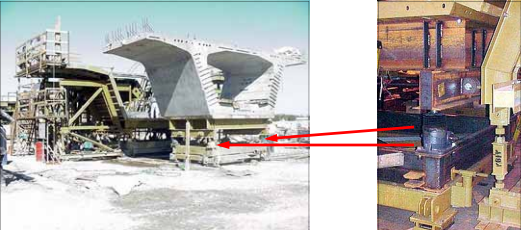

Everest Equipment Inc. of Ayer’s Cliff, Quebec manufactures both pre-cast formwork for segmental roadway construction and snow removal equipment.

To assist in meeting the critical tolerances required in their segmental formwork alignment, Everest has designed unique positioning tables using Joyce brand screw jacks.

In this application, four 30-ton worm gear screw jacks with a clevis end and pin upper connections are mounted on each corner of the positioning device’s lower frame. Due to the use of the clevis and pin connection, the jacks can be used to tilt the soffit form support frame at different angles and skewed elevations. Once the correct angle is achieved via the four independently adjustable screw jacks, the self-locking nature of the screw jack design allows the tables to support the dry cast and wet cast segments weights in the forms. Joyce also provided boot covers to protect each screw rod from job-site contaminants.