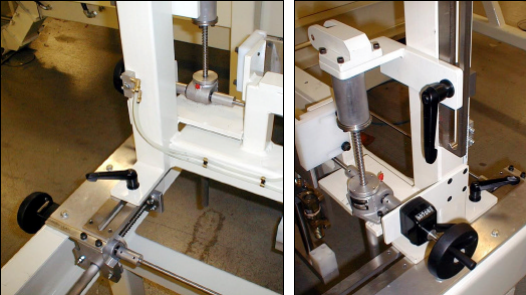

Screw Jacks Used in Packing Machinery

| Model | Capacity | Ratio | Rise | Screw Type |

| WJ500 | 500 lb. | 5:1 | 14” and 18” | Translating |

Features

- Twinned jacks result in precise alignment of package guides

- Repeatable positioning

- T2 load pad end condition on screwjacks

Everest Equipment Inc. of Ayer’s Cliff, Quebec manufactures both pre-cast formwork for segmental roadway construction and snow removal equipment. To assist in meeting the critical tolerances required in their segmental formwork alignment, Everest has designed unique positioning tables using Joyce brand screw jacks. Edson Packaging Machinery Ltd. in Hamilton, Ontario uses a number of Joyce® brand screwjacks in their custom-manufactured case packing machinery. Specifically, the screwjacks are twinned together and powered manually via hand-crank to move package positioning guides along multiple axes within the machinery. Machines may be adjusted as often as two to three times per day to suit runs of different sized packaging. The key benefit of using this mechanical system is that it provides precise, repeatable alignment of the package positioning guides. A counter is used in conjunction with the screwjacks to measure movement. Therefore, counter settings to suit various package sizes can be determined to allow machine operators to quickly and accurately reset the machine time after time.