Machine Screw Jacks Incorporated into Receiving Table in the Automotive Industry

| Model | Capacity | Ratio | Rise | Screw Type |

| WJ250-6-UP-TZ | 250 | 5:1 | 6″ | Machine |

Features

- Circular load pad end condition

- Cost effective solution

Goodyear Canada, located in Quebec City, manufactures a variety of molded rubber components for the automotive industry. When the company took on new contracts for molded rubber goods for several new vehicles, they were faced with a material handling problem in the heating machine area: Goodyear’s existing stationary receiving table, designed to receive a single size of mold for a single type of vehicle, needed to be redesigned to accommodate molds of various sizes.

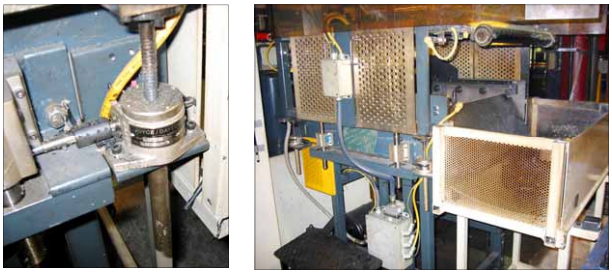

This particular receiving table catches each mold as it is ejected from the heating machine and presents it to a second machine for the rubber products to be extracted. Rather than purchasing new equipment, the company consulted with Trans-Quip Inc. and opted to add four WJ250-6-UP-TZ Joyce machine screw jacks to their receiving table along with a small motor and other powertrain accessories. The screw jacks allow the platform to

automatically rise and lower to accommodate the variety of mold sizes being processed — a successful and cost effective solution.